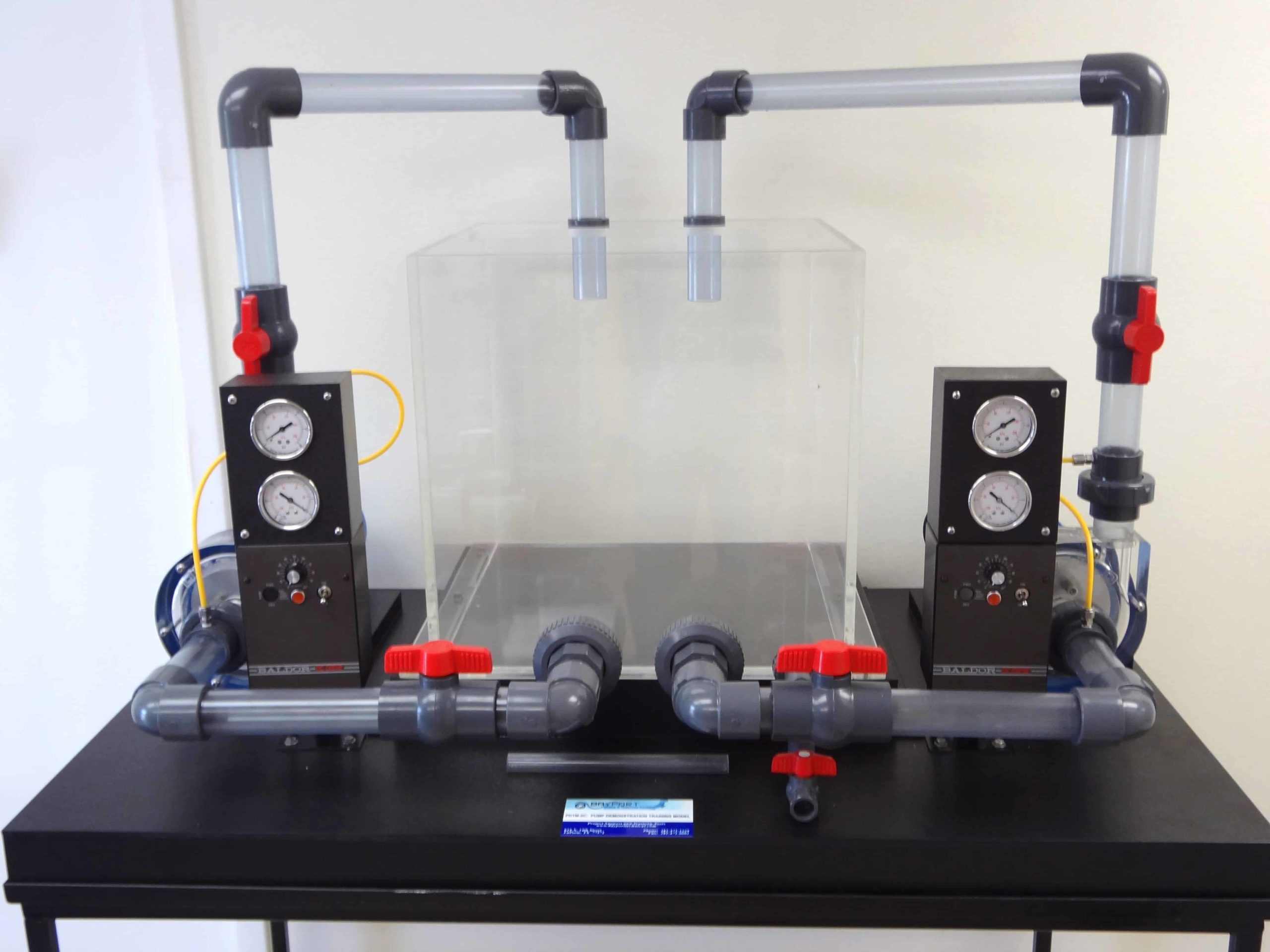

Bayport Technical's Dual Pump Working Demonstrator (102-PDTM2C) is a see-through training model possessing many features which can be used to train operators on the workings of disc pumps. By manipulating the suction and discharge valves and the RPM’s, students can demonstrate how this type of pump prevents cavitation and can handle a large amount of air entrained in the fluid (pseudo-cavitation/aeration). In fact, dual pumps allow the operator to run one in normal mode, while the other can show the results of aeration or reduced fluid flow at the pump’s inlet.

Disc pumps move liquids using the boundary layer and viscous drag principle. As the disc spins, it creates a boundary layer of fluid that pulls additional fluid into the pump. As the liquid leaves the pump, it begins to slow down thus creating pressure. Fluid pressure moves the process (liquid) through the pipes in a refinery or chemical plant.