Centrifugal pumps are mechanical devices designed to move fluids through the transfer of rotational energy from one or more driven rotors, called impellers. Fluid enters the rapidly-rotating impeller along its axis and is cast out by centrifugal force along its circumference through the impeller’s vane tips.

The action of the impeller increases the fluid’s velocity and pressure and directs it towards the pump outlet. The pump casing is designed specifically to constrict the fluid from the pump inlet, direct it into the impeller, and then slow and control the fluid before discharge.

Centrifugal pumps feature simple designs that are easy to understand, operate, and maintain. They offer a low-cost solution to most low-pressure, high-capacity pumping applications involving low-viscosity fluids, such as water, solvents, acids, bases, organics, chemicals, and light oils.

Common centrifugal pump applications include water supply and circulation, irrigation, and chemical transfer in petrochemical plants. Most pumping units are sold as pump skids that include the pump and motor coupled together and mounted on a steel baseplate.

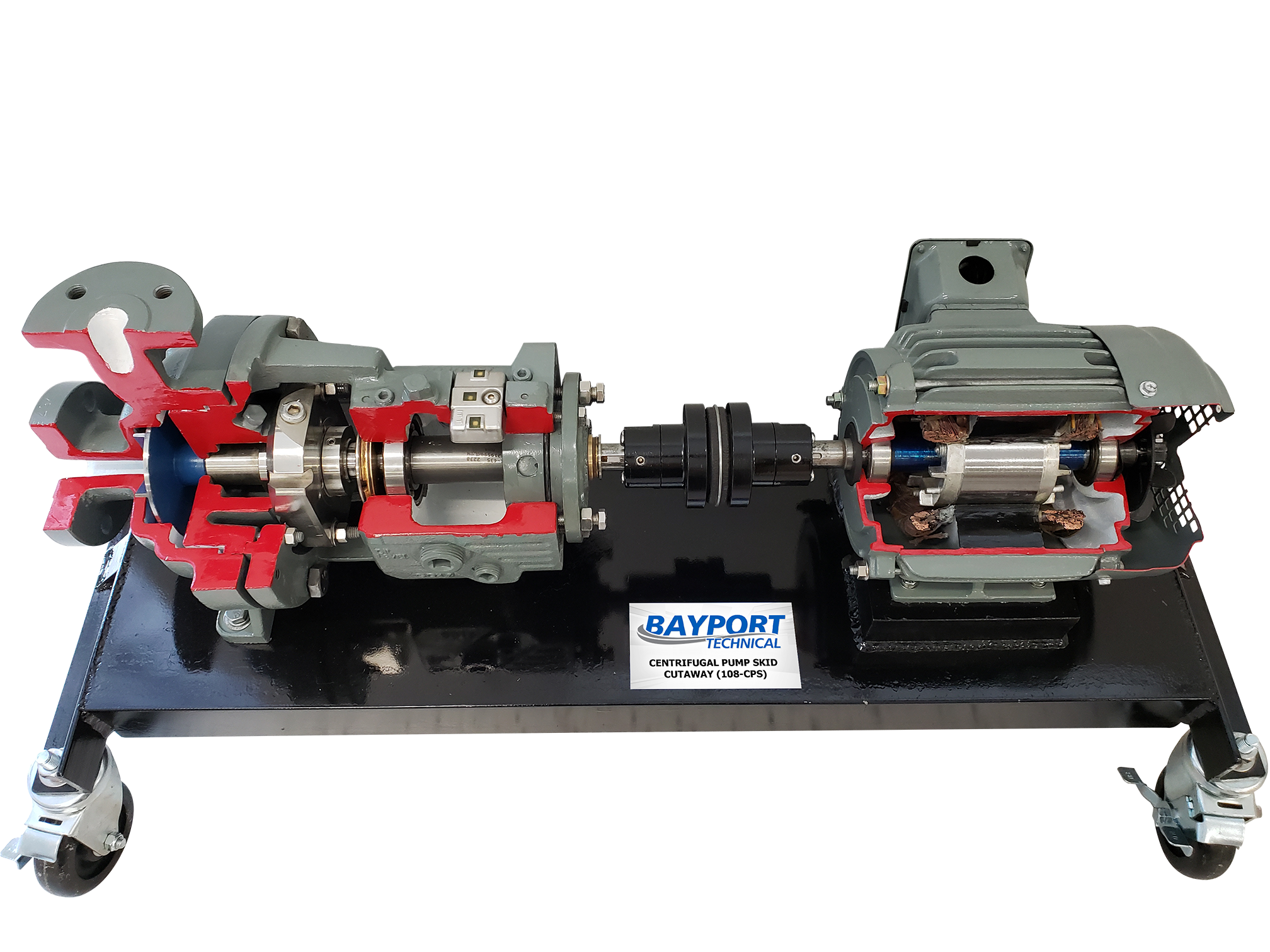

Bayport Technical's Centrifugal Pump Skid Cutaway (108-CPS) allows individuals to see and identify the internal components of a centrifugal pump and electrical motor. NOTE: Pictures of cutaway models are representative of our products; actual equipment, size, and color scheme may vary with each piece according to availability and customer preference.