Mechanical Skills Essential for Industrial Maintenance Technicians

Is there anything more glamorous than the life of an industrial maintenance technician? Overheating motors, cavitating pumps, misaligned shafts, worn belts, and seized bearings represent just a few of the common mechanical issues a technician might encounter daily.

Knowing how to fix these issues and, perhaps more importantly, how to conduct preventive maintenance to avoid these issues altogether remain two of the most important qualities of a highly skilled industrial maintenance technician.

Indeed, routine and preventive mechanical maintenance goes a long way toward ensuring that an industrial facility operates at peak efficiency. Maintenance technicians must possess a wide variety of basic mechanical skills, including the ability to operate, maintain, troubleshoot, and repair a broad range of equipment, such as pumps, engines, turbines, AC and DC motors, bearings, couplings, and belt and chain drives.

How do you ensure that your technicians have the skills they need? Fortunately, you don’t have to be an expert on training to see that your workers learn the knowledge and skills they need to keep your facility running efficiently and effectively. Trust the experts at Bayport Technical to provide the training tools you need.

Bayport Technical’s Standard Multiple Mechanical Training System (150-SMMT) provides maintenance and operations personnel with hands-on experience with a variety of common mechanical components. Using one comprehensive training unit, workers can practice a full range of essential skills related to common situations they’ll encounter in the industrial workplace.

For example, the Standard Multiple Mechanical Training System teaches mechanical skills related to vertical and horizontal shaft alignment, gear drives, belt drives, chain drives, electric motors, pump maintenance, and lock-out/tag-out training.

Users will gain hands-on experience with a wide variety of industry-standard equipment and components, including: a variable speed DC motor, centrifugal pump, vertical shaft alignment tower, belt drive, chain drive, gear reducer, right angle drives, pillow blocks, and multiple types of bearings and couplings.

Visit Bayport Technical’s website to learn more about the Standard Multiple Mechanical Training System, as well as the wide variety of other technical training products available.

- Published in News

Building a Mechanical Drives Training Program | Amatrol & DAC Worldwide Offer Complementary Training Solutions

To read ‘Building a Mechanical Drives Training Program’ as a Multimedia presentation, please click here.

Essential workers come in all shapes and sizes.

Without properly functioning mechanical drives, robots wouldn’t be able to perform automated commands, conveyor belts would lay still, and machining centers would grind to a screeching halt. Machine breakdowns couldn’t be fixed without them.

Local industry needs more technicians with specific skillsets, including proficiency in working with mechanical drives. What’s needed are more in-depth programs that not only provide hands-on skills, but take learning beyond the classroom with full, interactive eLearning.

With traditional education facing unprecedented uncertainty, building a sought-after Mechanical Drives Training Program is becoming a high priority for high schools and colleges around the nation. And thanks to Amatrol and its new sister company, DAC Worldwide, constructing a dream Mechanical Drives Training Program is now easier than ever.

What Good Comes With Mechanical Training?

Frankly, mechanical drives are found in almost every aspect of life and countless industrial sectors, such as agriculture, pharmaceuticals, automotive, construction, power & energy, industrial maintenance, mining, and more.

Thanks to its worldwide use, mechanical maintenance technicians are highly sought after. Positions are available, with more on the way thanks to a large chunk of Baby Boomers approaching retirement age.

However the importance behind mechanical training can eventually be attributed to the impending Skills Gap, which has the potential of leaving millions of jobs unfilled due to a lack of qualified workers. Thanks to equipment that is becoming more technologically advanced by the day, few can perform routine maintenance that must be learned and practiced to gain proficiency.

Today, mechanical maintenance technicians are expected to possess a very specific, highly technical skillset. So in order to meet those expectations, current mechanical training should cover everything from bedrock fundamentals, all the way through advanced manufacturing applications.

In addition, the training should not be one-dimensional. While hands-on training allows students to take a more tangible approach to training, theoretical understanding of the topic brings the knowledge full circle. One without the other would be doing a disservice to not only the students, but any customers they may encounter on their professional journey.

How DAC Worldwide & Amatrol Can Legitimize Your Mechanical Drives Training

No matter how advanced your mechanical drives training may (or may not) be, Amatrol and DAC Worldwide can add the substance to take your program to the next level.

DAC Worldwide and Amatrol joined forces in 2019 after discovering that their training systems complemented each other to create an ever more robust training. As worldwide leaders in technical training, the goal of the “sister companies” was to provide even more technical training opportunities for schools and companies in need, especially in the field of mechanical drives.

However the real winners in the combining of these two technical training companies? The learners. While Amatrol and DAC Worldwide may be in the forefront of technical training, the approach taken by the two companies varies slightly.

What this means is even more opportunities for learners to strengthen their skills before entering the workforce. It also gives schools and training facilities more options when building their program, as Amatrol’s and DAC Worldwide’s products complement each other for a well-rounded classroom.

For example, Amatrol has unmatched eLearning curriculum, as well as unparalleled depth and breadth of coverage. The learning systems, which are available in both portable and full-size models, offer thorough, in-depth training that can be added on as training needs grow or change. A typical lesson will see students start with the basics, like identification and definition, before moving on to more challenging topics, like troubleshooting and implementation.

DAC Worldwide, on the other hand, creates training systems, models, cutaways, and sample boards of various mechanical drives. Each product is intended to train students on a specific set of technical topics. So if instructors have a particular skill they have identified as the most appropriate – like belt drive training (201-000) – a DACW training system will focus solely on that particular skill. Or for those that need a perfect tool for skill evaluation for pre-hire or annual skill testing, DAC Worldwide’s products would be the ideal solution. In turn, with its focused scope, these trainers could be a less expensive alternative to large-scale systems.

Amatrol and DAC Worldwide Mechanical Training Solutions

As mentioned, both Amatrol and DAC Worldwide provide mechanical training, but do so in slightly different, yet complementary, closely-aligned ways that further enhance training.

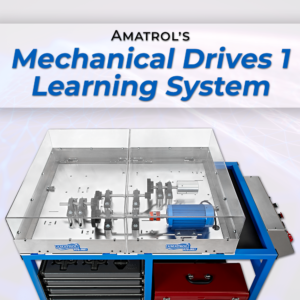

Amatrol built a platform that has a broad range of skills on its base levels, with the opportunity for expansion. By adding an optional system, users can create a system that is unmatched in its depth and breadth of training. Amatrol’s Mechanical Drives 1 Learning System (970-ME1) does it all in a compact system and also includes interactive eLearning.

DAC Worldwide, on the other hand, built individual systems that focus on more specific skill training. Users can easily expand the number of trainers used for more in-depth skill-building, or use the trainers as a tool for learners’ final assessment. It’s also ideal for adult training, if local industry wants their employees to have specific training, such as coupling alignment (206-000), without the need for belts, chains, and other components.

While both approaches lead to successful technical training, many of DAC Worldwide and Amatrol’s products work hand-in-hand for seamless integration into any Mechanical Drives program.

So if you’re looking for a way to expand (or begin) a Mechanical Drives Program, here are a few solutions on how to implement trainers from both DAC Worldwide and Amatrol:

Solution #1: Mechanical Drives Learning System | 970-ME1 (Amatrol)

The “crown jewel” of mechanical training products, Amatrol’s 970-ME1 covers countless industry-needed skills in one convenient system. The Mechanical Drives 1 Learning System covers alignment and operation of mechanical drives, and alignment and applications of various motor drive systems.

Accompanied with online mechanical drives curriculum to gain theoretical knowledge, this system also provides hands-on skill training for shaft, belt, gear, and chain drives using real-world motor drive components. Students will cover topics like mechanical drive systems, key fasteners, power transmission system, v-belt drives, and much more.

With the 970-ME1, Amatrol expertly mixes theoretical concepts immediately followed by hands-on practice to build the strongest possible retention and competency for learners. It includes Amatrol’s world-class eLearning curriculum, as well as expansion units to further training, such as:

- Mechanical Drives 2

- Mechanical Drives 3

- Mechanical Drives 4

- Laser Shaft Alignment*

- Vibration Analysis*

- Roller-Pack Machine Tool Axis

- Plain Bearing Machine Tool Axis

- Floor-Standing Belt Conveyor

- Machine Tool Chip Conveyor

- Predictive Maintenance Vibrations Analysis

* Also Available as Stand-Alone Training System

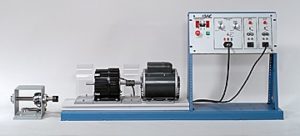

Solution #2: Single-Topic Trainers (DAC Worldwide)

Single-topic trainers focus on one core subject matter, making it useful for applications where there is a greater need for training on a specific topic. Not only can these DACW trainers extend your training lab to accommodate more students at a very low cost, but they can add to Amatrol’s 970-ME1 system.

Belt & Chain Drives

DACW’s Belt Drive Training System Plus (201-PAC) focuses on the identification, installation, tensioning, and alignment of common belt drives types found throughout industry. It includes flanged bearings, fractional horsepower belts and sheaves, multiple Type-A belt sets, sheave bushings, and more.

Available in: 201-000, 201-PAC

The Chain Drive Training System Plus (223-PAC) presents learners with industrial chain drives, heavy/silent chains, and sprocket set usage, providing a complete introduction to chain nomenclature, assembly, disassembly alignment, and maintenance.

Available in: 223-000, 223-PAC

Gear & Bearing Maintenance

DAC Worldwide’s Gear Maintenance Training System Plus (205-PAC) is the ideal training tool to learn how to install, align, troubleshoot, and repair a wide variety of gears, shafts, and bearings. Learners will be introduced to gear identification, installation, alignment, and troubleshooting.

Available in: 205-000, 205-PAC

The Advanced Bearing Maintenance Training System Plus (204E-PAC) allows for in-depth training in the identification, installation, and removal of various industrial-quality rolling element bearings. Using two workstations, students will study topics such as bearing identification systems, rolling element bearing construction, bearing maintenance pre-check, and more.

Available in: 204E-000, 204E-PAC

Coupling / Shaft Alignment

For convenient, realistic training in shaft alignment, look no further than DAC Worldwide’s Basic Coupling / Shaft Alignment Training System Plus (208D-PAC). The design is based on the configuration found in many vertical centrifugal pumps, and accommodates all types of alignment apparatus, including laser systems. Learners will perform four-point motor element jacking, master a dial indicator in coupling/shaft alignment, troubleshoot angular and parallel misalignments, and install a flexible disc coupling.

Available in: 208D-000, 208D-PAC

Brake Clutch

Using a completely motorized training package of brake and clutch-related hardware and control components, DACW’s Brake Clutch Training System (220-PACP) explores how brakes and clutches are used for training throughout various sectors. The trainers covers the installation, operation, and troubleshooting of brakes and clutches in a variety of applications.

Using a completely motorized training package of brake and clutch-related hardware and control components, DACW’s Brake Clutch Training System (220-PACP) explores how brakes and clutches are used for training throughout various sectors. The trainers covers the installation, operation, and troubleshooting of brakes and clutches in a variety of applications.

Available in: 220-000, 220-PACP

Solution #3: Enhancement Trainers (DAC Worldwide)

In addition to single-topic trainers, DACW also offers Enhancement Trainers.

Basically, Enhancement training systems cover skills that are not currently included in Amatrol training systems, specifically the 970-ME1. These units have the same look and feel as single-topic trainers, but can extend the training capabilities of Amatrol mechanical learning systems.

Advanced Coupling / Shaft Alignment

DAC Worldwide’s 3-Component Coupling Shaft Alignment Training System Plus (206-PAC) is patterned after a typical turbine-driven pump or turbo-compressor. The system includes flanged bearings that allow changes in angular and parallel misalignment, motor attachment points with steel-threaded inserts, and replaceable shaft for easy installation of bent shafts.

Available in: 206-000, 206-PAC

With a design based on the configuration found in many vertical centrifugal pumps, DACW’s Vertical Coupling / Shaft Alignment Training System Plus (207-PAC) features industrial-grade components to perform a four-point motor element jacking, install a flexible disc coupling, and troubleshoot angular and parallel misalignments.

Available in: 207-000, 207-PAC

Fan Balancing

DAC Worldwide’s Fan Balancing Training System Plus (202-PAC) encourages learners to gain experience with fan balancing in an effort to achieve maximum fan efficiency and stability. Designed to look and perform like a typical squirrel cage fan, it comes with movable pillow block assemblies and can feature even or odd number blade configurations.

Available in: 202-000, 202-PAC

Vibration Analysis

Using DACW’s Vibration Analysis Training System Plus (203-PAC), students will be introduced to a versatile, precision-machined device that isolates individual, vibration-causing variables in order to demonstrate their individual signatures. Topics include effects of frequency/displacement, proper pick-up mounting, correcting vibrations caused by imbalance and misalignment, and more.

Available in: 203-000, 203-PAC

Advanced Bearing Maintenance

The Journal and Fluid-Film Bearing Training System Plus (204J-PAC) trains learners in the identification, installation, removal, and maintenance of a variety of Babbitt-type journal bearings found on high horsepower, high-speed rotating machines. Using two workstations, students practice common maintenance tasks, such a bluing check, dent repairs, and hand scraping.

Available in: 204J-000, 204J-PAC

Let Amatrol and DAC Worldwide Help You Build Your Ideal Mechanical Training Program

No matter what kind mechanical training you’re looking for, or what skills you’d like to focus on, the world-class training tools of Amatrol and DAC Worldwide should have you covered. With almost 80 combined years of technical training experience, no other company on the market can match us!

For more information on how to build your ideal mechanical training program, please click here.

- Published in News